50 Hz End Suction Pump

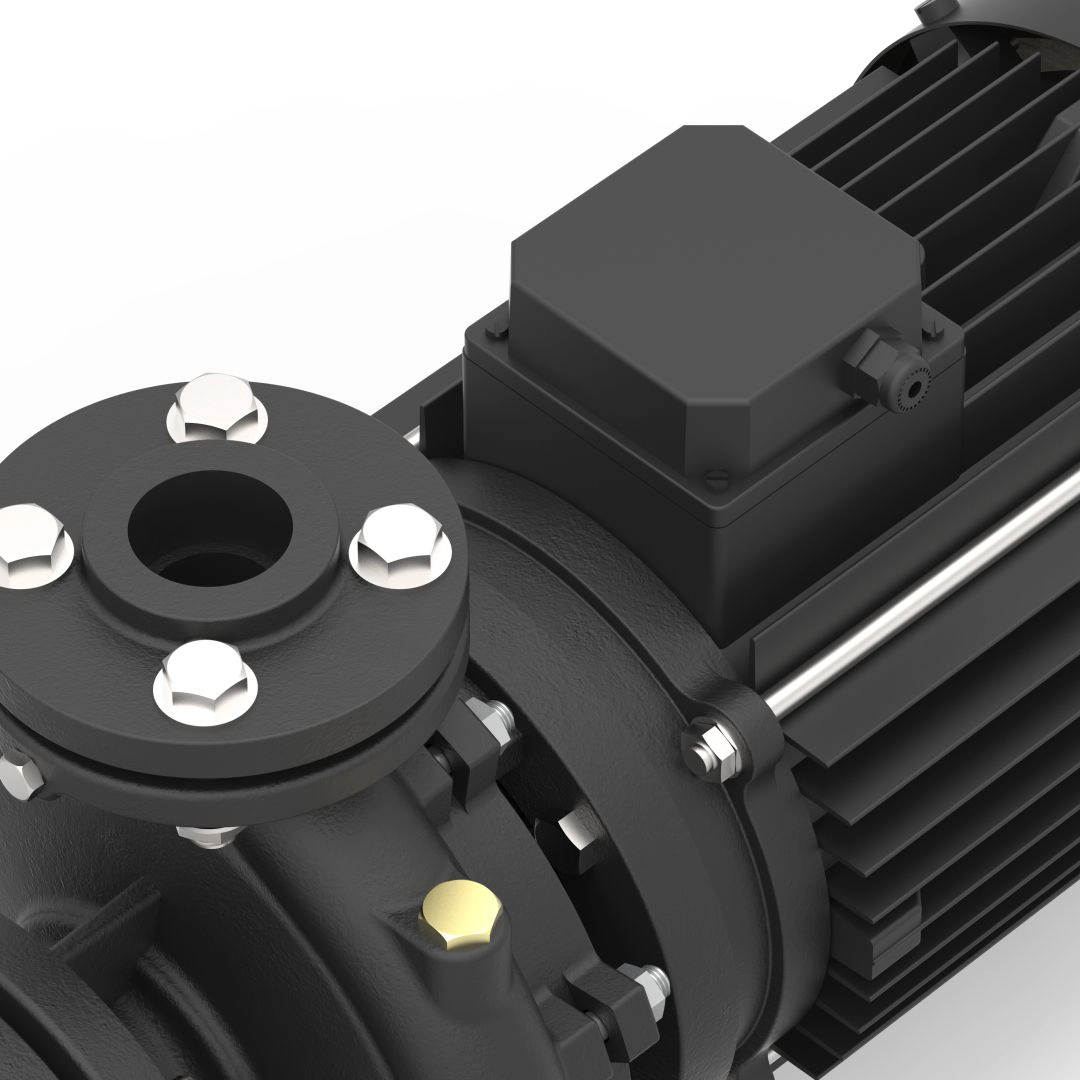

The End Suction Pumps are the most basic types of centrifugal pump characteristically configured with a casing. The pressure is present on one end as well as the discharge is located at the top. These pumps normally encompass an impeller as well as a casing that has coil windings. The high velocity of these pumps is transformed into high pressure via a process of diffusion. The frame-mounted group of End Suction Pumps comes with a twofold volute design. The main attributes of these pumps are their design as well as their boosted efficiency and reduced life cycle costs.

Description

The End Suction Pumps are the most basic types of centrifugal pump characteristically configured with a casing. The pressure is present on one end as well as the discharge is located at the top. These pumps normally encompass an impeller as well as a casing that has coil windings. The high velocity of these pumps is transformed into high pressure via a process of diffusion. The frame-mounted group of End Suction Pumps comes with a twofold volute design. The main attributes of these pumps are their design as well as their boosted efficiency and reduced life cycle costs.

Product Description

| Theory | Centrifugal Pump |

| Max Suction | 150 mm |

| Flow Rate | 1 to 156 m3/hr |

| Inlet/Outlet | 25 to 150 mm |

| Head Size | 1 to 55 MTr |

| Material | CI, SS304, SS316 |

| Structure | Single Stage Pump |

| Power | Electric |

| Fuel Type | Other |

| Pressure | Medium Pressure |

| Usage | Paper Printer, Automobile, Water |

| Application | Submersible, Fire |

| Seals Type | Mechanical seals |

| Priming | self Priming |

| Brand | LUBI / CRI / Kirloskar |