50 Hz Bare Shaft Pump

Pumps are designed for non explosive liquids which are clean and thin without any solid particles. For aggressive liquid please ensure that material of construction is suitable for liquid to be pumped. If liquids with a viscosity higher than that of water, are to be pumped the power consumption of the pump will increase with increase in viscosity. This will require a large motor for the pump. Head, discharge and pump efficiency will reduce with increase in viscosity. When pumping liquids with a density higher than that of water, the power consumption of the pump will increase at a ratio corresponding to increase in density

Description

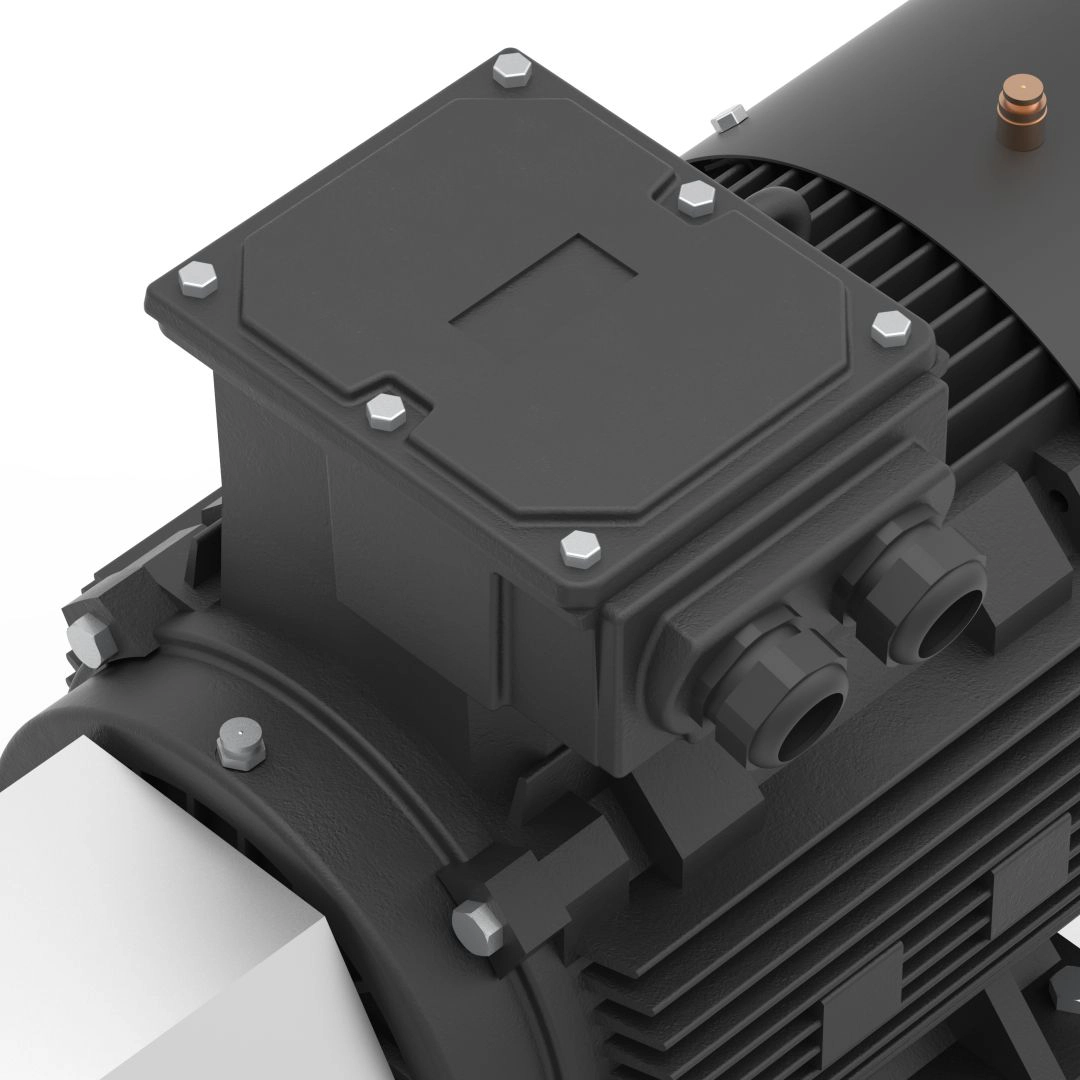

50 Hz Bare Shaft Pumps come with various impressive features such as back pull out designs, renewable wear parts, hard bearing, interchangeable parts, robust shaft bearings, easy impeller adjustments and countless sealing options. Fabricated of cast iron, the pumps are the non-self-priming devices rendered with radial suction as well as discharge ports. These are delivered with state-of-art techniques with a wide ambit of hydraulic conditions ensuring supreme efficiency. The 50 Hz Bare Shaft Pumps have a design that is perfect to balance hydraulic axial thrust. These are available with numerous liquid end offerings and an expanded volume range. Â

Product Specifications

| Inlet/Outlet | 50 MM |

| Flow Rate | 1 TO 1060 M3/HR |

| Max Suction | 300MM |

| Head Size | 1 TO 158 MTR |

| Theory | Centrifugal Pump |

| Material | CI, SS304, SS316 |

| Structure | Single Stage Pump |

| Power | Electric |

| Fuel Type | Other |

| Pressure | Medium Pressure |

| Application | Maritime, Fire |

| Seals Type | MECHANICAL SEALS |

| Priming | SELF PRIMING |

| Brand | LUBI and CRI |

Features

- The pump casing shall have material of construction of Cast Iron FG 260 (standard supply), CF8, CF8M, axial suction and radial discharge port, dynamically balanced impeller, steel shaft, stainless steel shaft sleeve.

- The pump shaft sealing will be by either gland packing or mechanical shaft seal suitable for 16 bar or 25 bar pressure rating based on shut off pressure of the pump.

- The pump shall have closed type impellers and bowl diffusers with material of construction stainless steel AISI 304 sheet metal, pump shaft shall be made of stainless steel AISI 316 material.

- The pump shall have back pull out design so as to enable the rotating parts to be removed and serviced without dismantling the suction and discharge pipe work.

- All cast iron parts shall be CED (cathode electrode deposition) coated for corrosion resistance with uniform coating and controlled deposition thickness of 20-30 microns.

FEATURES AND BENEFITS

- The pumps are non-self priming, horizontal, single-stage, end-suction pumps with axial suction port & radial discharge ports.

- Standard flanges for suction and discharge ports will be PN 16 as per DIN standard EN 1092-2 and PN 25 as per DIN standard EN 1092-2. ANSI 125 and ANSI 250 as per ASME B16.1 are available on request.

- Performance and dimensions comply to ISO 2858.

- These pumps are long coupled pumps with TEFC squirrel cage induction motor with main dimensions complying to IEC standards and mounting designation B3 (IM 1001).

- These pumps are available with gland packing as well as mechanical shaft seal.

- The pump impellers are dynamically balanced to grade 6.3 of ISO 1940.

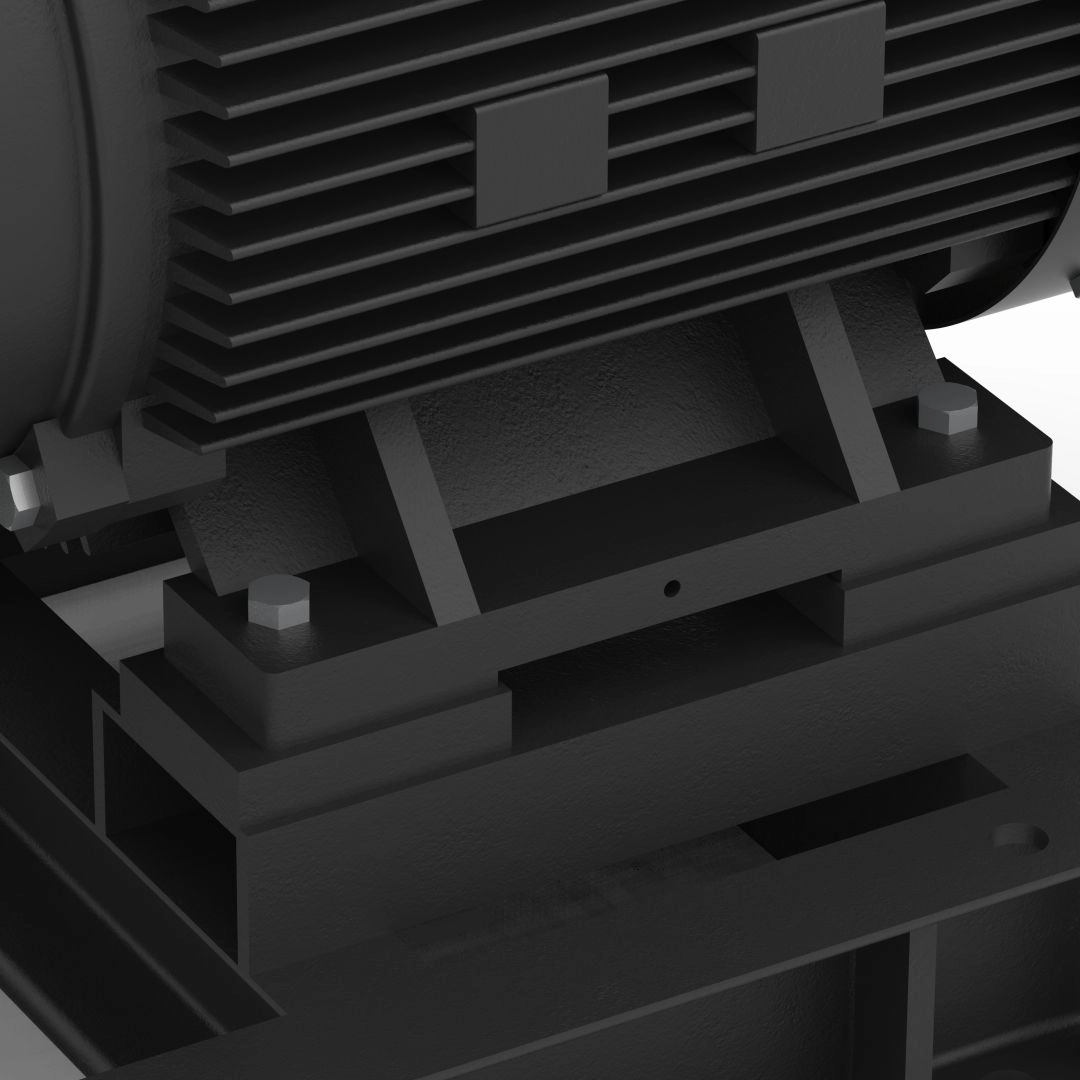

- These pumps and motors are available with fabricated steel base frame according to EN 23661.

- These pumps are available with our standard range of motors complying to EFF2 motors. They can also be supplied with EFF1 motors on request.

- These pumps feature the back pull-out design. The user can remove the motor, bearing bracket & impeller for servicing without disturbing the volute casing and the suction & delivery pipes.

Applications

- Water supply.

- Pressure boosting for high rise buildings, hotels industry etc.

- Industrial washing & cleaning systems.

- Fire protection systems.

- Cooling & Air Conditioning systems.

- Boiler feed & condensate transfer system.

- Irrigation systems for fields including sprinkler & drip irrigation systems.